Your operator will be trained in Peddimat. You might have customers who bring a couple of pieces with them.

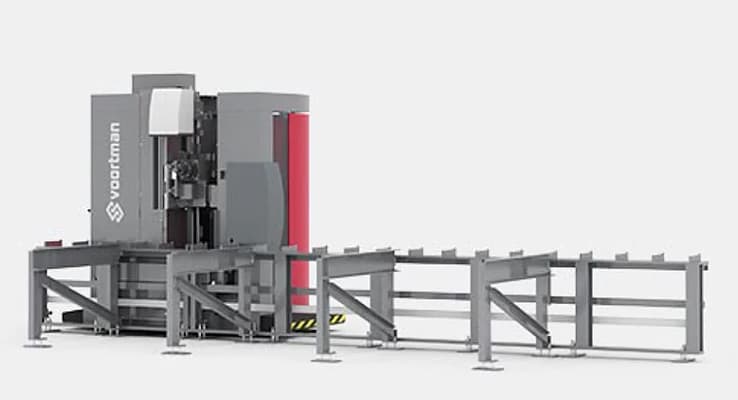

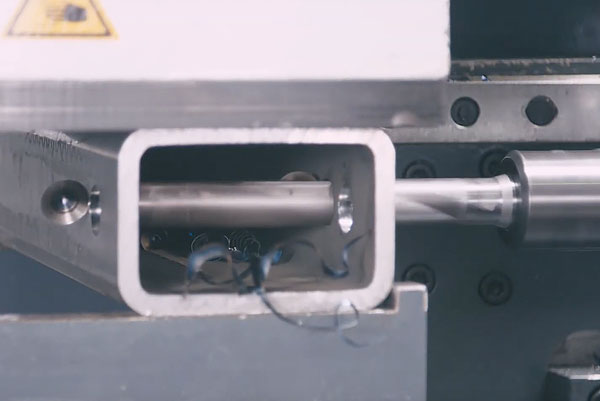

What good is a CNC drill line if it doesn't position a fabricator to compete at a high level in the steel fabrication arena. The Advantage-2 has the functionality to process technical programs with intelligence and speed. Equipped with three five-station tool changers, each drilling axis has the capability to drill, mill, countersink, tap and scribe. This drill line can also be equipped with a Signoscript underside scriber or Signomat part stamping unit. Part information is retained even after painting, blasting and galvanizing processes. Minimizing shop errors? Check. Carbide tooling gives the Advantage-2 more aggressive drilling and a higher quantity of holes than any drill line before it. The high torque drilling axes have a thicker more aggressive cut removing more chips with each rotation. This drill line will chew through beams, channel, angle, tube and even flat bar. With a processing window of 44 inches wide and 18 inches tall no profile can escape the reach of the Advantage-2.