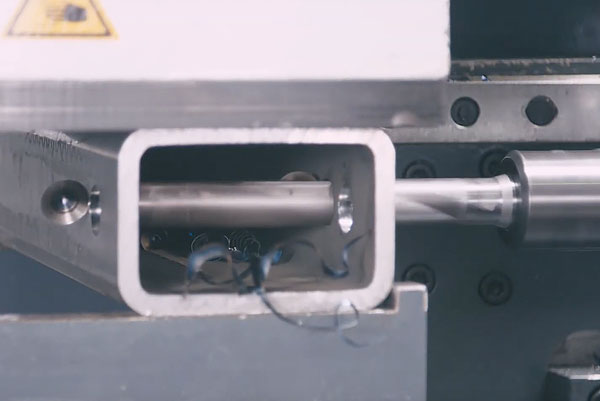

Since 1950, we have been designing machines and solutions to help you as a steel fabricator. Automation is our response to ever-decreasing labor availability and rising labor cost. We can help you lower production costs and improve your margins. Voortman's CNC Beam Drill line can guarantee the highest productivity, accuracy, reliability and quality. Our CNC Beam Drill Lines include many functions, including drilling, milling and marking as well as countersinking, thread tapping, and other functions to optimize productivity and increase automation. Voortman has a wide range of Beam Drill Lines to suit every production and company.

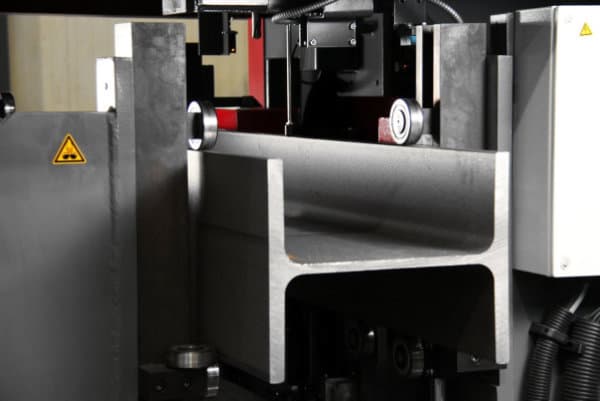

Voortman machinery is the worldwide leader in structural steel fabrication technology. Voortman machines provide steel fabricators with an advantage in the steel sector and allow them to maximize tonnage. Advantage-2 CNC beam drill is the core of any structural-steel fabrication shop. This machine is the heart of it all. It can drill endless carbide holes at high speeds, with multiple spindles, and at high speed. Advantage-2 is the most productive drill line in the steel sector. This drill line supports shops over the long term thanks to its heavy steel frame. The Advantage-2 is able to run profiles from one end to the other without any stops in production thanks to its roller feed design for the outfeed and infeed. Many fabricators around the globe use their Advantage-2s every year to make hundreds of thousands of tons steel.