Cnc Drill Line Job

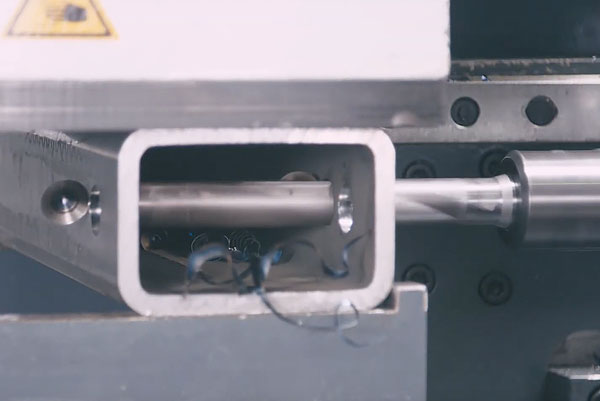

Based on the current pricing of the different suppliers, we believe the customer is better off getting good quality Ocean Penetrator twist drilling bits and a sharpener.

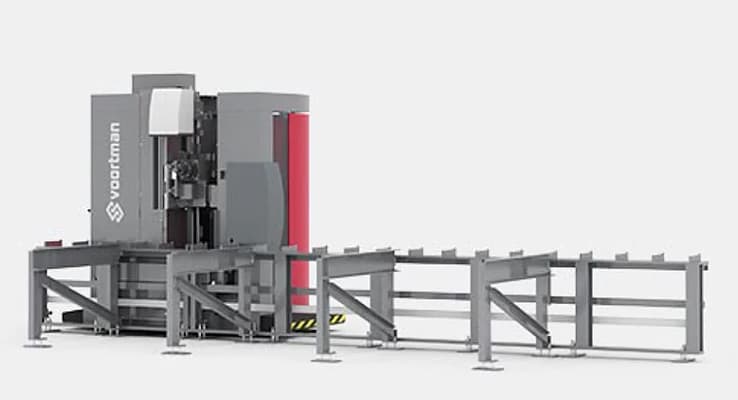

Voortman's inside service technicians don't often need to be present at your machine in order to fix a problem. Voortman technicians can operate your control using an internet connection. Voortman equipment uses the Powerful Windows(r), Siemens control that allows for this capability. It also provides superior diagnostics via Windows(r).