Cnc Drill Line Equation Calculator

Peddimat has a simple, intuitive interface that is easy to understand.

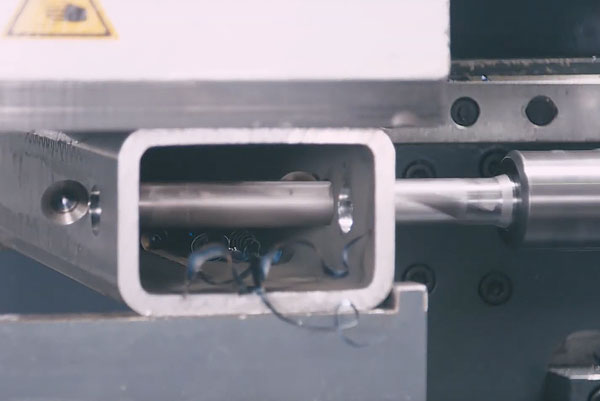

The intelligence of a Voortman designed beam drill line is not only in its own capabilities but in its ability to be plugged into any environment through its modularity. Tandem solutions with band saws, robotic coppers and PeddiWriters further expand the shop's throughput positioning for a more economic approach when the steel industry cools down and a more aggressive approach when it heats back up. Voortman designed the Multmaster to help advance even the smallest parts into a tandem bandsaw. Utilizing the whole profile and minimizing the remnant leads fabricators toward better profits. More output? Check. As with any Voortman CNC drill line profit wouldn't be possible without material handling. Not only do fabricators lose money every time a profile is manually moved, but material handling is much safer for transferring the heaviest profiles when compared to fork trucks or cranes.