Cnc Drill Line 02

Material handling allows multiple CNC machines to be connected and maintains material flow through a shop. This allows fabricators the opportunity to continue growing as their business grows. Only the Advantage-2 high-speed drilling line can produce 150 tons of metal per 40-hour working week. This is the perfect drill line for small and large fabricators worldwide. Complete stop. Voortman puts the success and well-being of the steel sector as his top priority. This is why we offer unsurpassed support and service. For more information about the most difficult steel fabrication machinery worldwide, contact us to request a demo. Voortman, we are stronger than any steel.

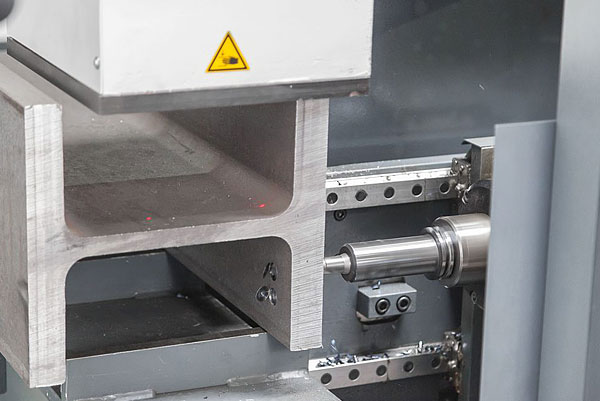

Our beam drill machines have central lubrication, a cooling system, and linear guides to make them easier to use and require less maintenance. Each coordinate system includes a 4 station tool changer. This allows it drill, mill/scribe, counter sink or tap as many times as required. Additionally, tools can be swapped easily during operation. Positive beam positioning is an arm that attaches to a rack on the conveyor. This allows the beam position to be more precisely controlled as it moves through a drill line.