Cnc Drill Line Corporation

".. This machine is intended for structural fabricators. However, I was able to see that it would be a good fit for drilling truck frames. Assembly was easy because of the repeatability and accuracy. Avenger drills the channels for one truck in two hours. If we were to do this manually it would take 16 hours. The Avenger has greatly increased our productivity and profitability !.."

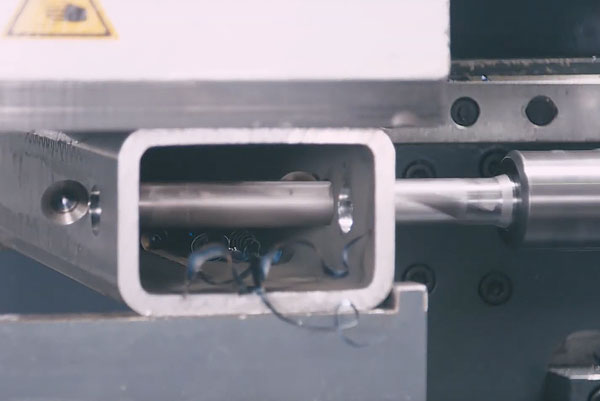

Continuous production? Check. It is more than just being able to manage processes. Fabricators must also be able to meet industry standards for quality and time management. Triple axis drilling allows for fast processing. The Siemens spindle motors are 25 horsepower and have industry-leading penetration times. Each axis is equipped with ball screw feed positioning. The drill line features an advanced clamping system to minimize vibrations due to its high power. Extreme accuracy Check.