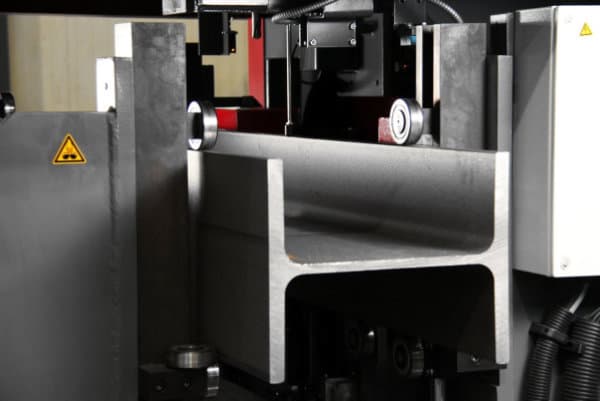

Cnc Drill Line 10mm

The CNC Drill Line is able to lay out and drill holes in any steel profile in half the time it takes with a mag drilling machine.

At GSS Machinery we are committed to providing you as many options as possible with regard to drilling with your CNC Drill Line or any other CNC Beam Drill Line.