What good is a CNC drill line if it doesn't position a fabricator to compete at a high level in the steel fabrication arena. The Advantage-2 has the functionality to process technical programs with intelligence and speed. Equipped with three five-station tool changers, each drilling axis has the capability to drill, mill, countersink, tap and scribe. This drill line can also be equipped with a Signoscript underside scriber or Signomat part stamping unit. Part information is retained even after painting, blasting and galvanizing processes. Minimizing shop errors? Check. Carbide tooling gives the Advantage-2 more aggressive drilling and a higher quantity of holes than any drill line before it. The high torque drilling axes have a thicker more aggressive cut removing more chips with each rotation. This drill line will chew through beams, channel, angle, tube and even flat bar. With a processing window of 44 inches wide and 18 inches tall no profile can escape the reach of the Advantage-2.

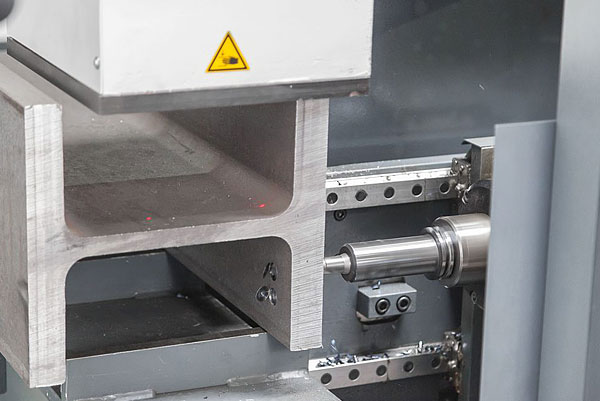

These drop in serrated grippers can be used to secure base plates and flat bar profiles, as well as angle and other profiles that may have rounded edges which want to push away at the datum line.