Cnc Drill Line Youtube

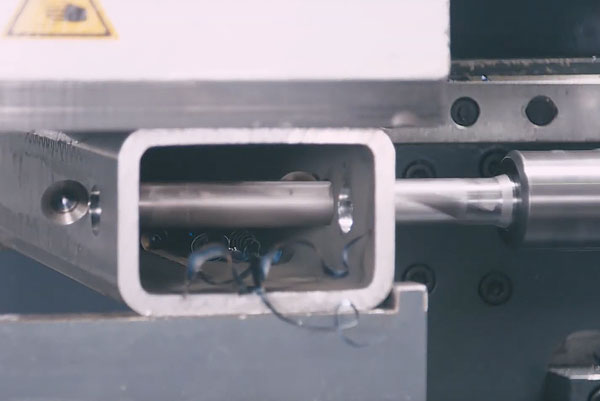

Advantage-2 carbide drills use electronic ball screw drive spindle motion and automatic tool change technology. The combination of Voortman's legendary build quality and mechanical design gives the best combination of strength, agility, and strength.

Auto Stand-Off is currently defined as surface stand-off. It should not be confused with vector standoff in 5-axis mode. Auto stand-off currently works on a changing surface. It adjusts vertically based upon the angle of the Axis. This means that five (5) axes are taken into consideration during calculations. However, this is not the same thing as tool vector standoff. You can change the vector standoff while the machine runs manually by pressing buttons on the screen.