Which is stronger T-beam or rectangular beam

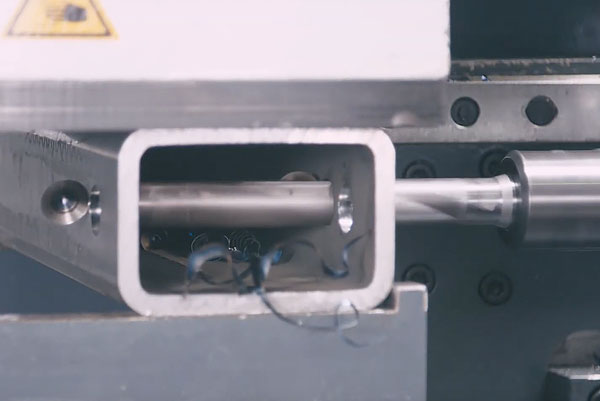

The CNC Beam Drill Line is the most affordable CNC beam drill line on the market today and ensures that the fabricators is the low-cost producer, allowing him to win more work and to make more margin.

A 4-axis layout marking attachment eliminates human error in manual layout methods. Part information is retained even after painting, blasting and galvanizing.