Ocean Avenger Cnc Beam Drill Line

Importing files directly into your steel detailing software is a better option. It eliminates unnecessary steps and can also prevent any incorrect data capture. This is a distinction that can be distinguished into two camps:

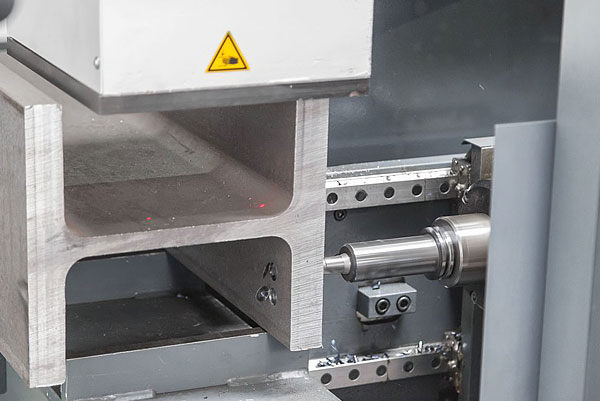

Automatic Edge Finder - The edgefinder can be used manual (Jogging Method and Screen Buttons), programmatically using M &G codes or fully automated with a dedicated program. This option sets offsets and rotates the program to match location and orientation on the cutting surface.