Cnc Beam Drill Line Up Chart

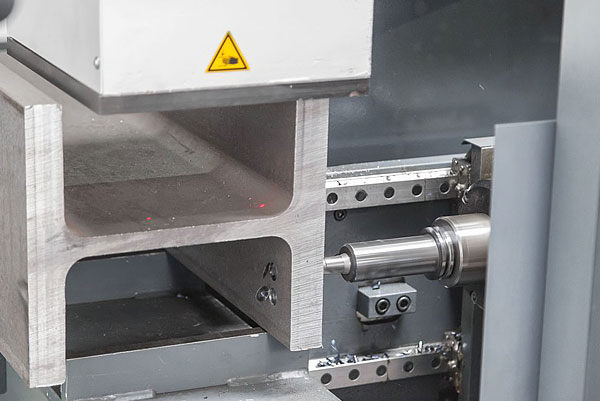

CNC Beam Drill Line will not only drill columns and beams but can also process all types of steel profiles such as channel, angle, flat bars, base plates and RHS square and circular profiles.

"..In our efforts to satisfy customer demands and increase productivity, we installed a new beam drilling line. This has resulted in a lower labor cost and faster turnaround times that have always helped us land high quality jobs.