Drill Machine

We believe that, based on current pricing, the customer is better served with good quality Ocean Penetrator Twist Drill Bits and a good sharpener.

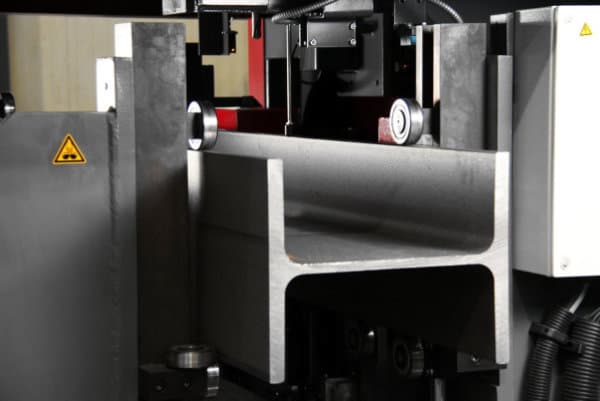

Voortman created today's CNC beam drill standard using time-tested technology. Advantage-2 processes on average 150 tons of steel per week. Advantage-2 uses the most efficient drilling and milling operations, including tapping, tapping, and countersinking.