R Cnc Code

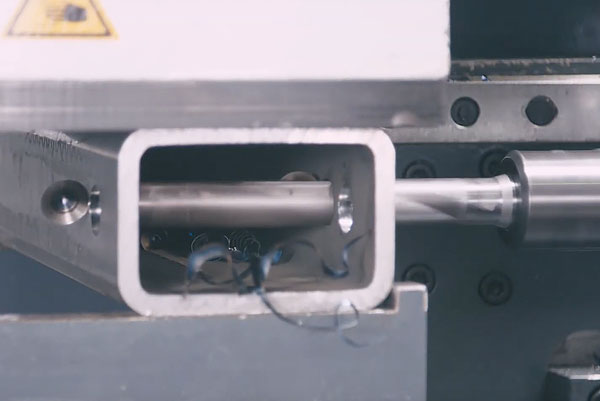

Advantage-2 employs support clamps that ensure the best rigidity for the workpiece. Carbide tool lives are best maintained with as little vibration as is possible.

You may choose between a Vertical Machine Center and a CNC router when choosing the CNC machine you want. Both of these pieces can be used for many purposes. Which one should you use?