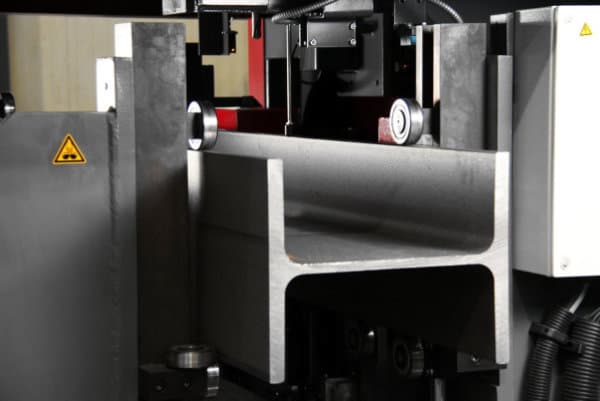

It is no good having a CNC drilling machine if it doesn�t enable a fabricator compete at the top of the steel fabrication field. Advantage-2 allows you to process technical programmes with speed and intelligence. Each drilling axis includes three five-station tool changers. Each can drill, countersink and tap as well. Signomat underside scribers or part stamping units are also possible to be fitted to this drill-line. Part information is kept even after blasting, painting and galvanizing. Minimizing shop errors? Check. Advantage-2 drills more aggressively and produces more holes than any other line of drilling. High torque drilling axes have thicker, more aggressive cuts that extract more chips with each turn. This drill line can eat through beams as well channel, angle and tube. Advantage-2 is able to process any profile up to 44 inches wide x 18 inches tall.

Voortman machines have been the global leaders in structural steel fabrication technology. Voortman machines are a key part of steel fabricators' competitive advantage. They can optimize tonnage and maintain a high level of quality. Advantage-2 CNC beam drilling is the heart of any structural steel fabrication shop. This machine is a core component of a high-speed multi-spindle, relentless caride drilling. Advantage-2 is one of the most profitable lines in the steel industry. This drill line is built from heavy steel and will last for many years. Thanks to the roller feed design of the infeed/outfeed, the Advantage-2 can run profiles from end to end without any stop in production. Every year, hundreds of fabricators around the world run hundreds of thousands and tons of steel through their Advantage-2s.