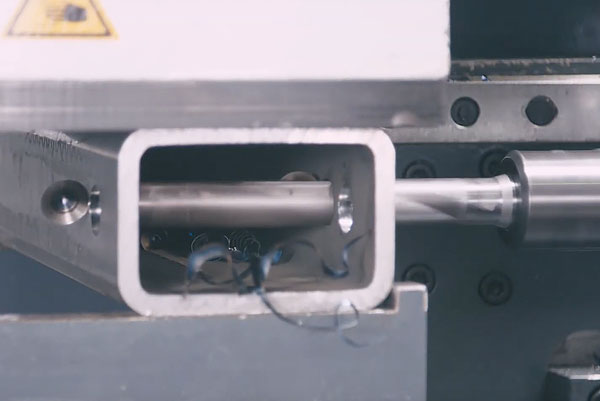

Our beam drill line machines feature central lubrication and linear guides. This ensures smooth operation and less maintenance. Each coordinate system has a 4-station tool changer that allows it to drill, mill and scribe as well as counter sink or tap. It can also swap tools mid-operation without any disruption. The positive beam positioning system consists of an arm attached on the feed conveyor to a rack-and-pinion system. This allows the beam to be positioned more precisely as it passes through the drill line.

"..We have drilled approximately 25.000 holes since we purchased our CNC Beam Drill Line four months ago. It used to take us 5 minutes to drill each hole. It now takes us approximately. It takes us 30 seconds per hole... that's a savings of 1875 hours over 4 months. This is equivalent to $84,375 in our shop. This machine will pay off in less than a year, as you can see. It not only speeds up production but also frees up space for more jobs.