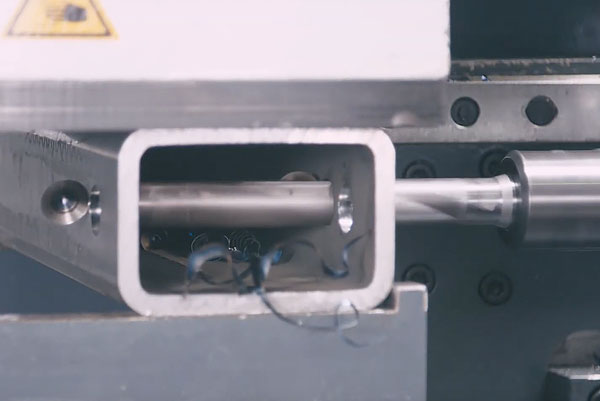

Structural Steel Beam

Yes. Outside, we have many CNC Beam Drill Lines. It is important to provide weather protection for both the control panel, and the moving mobile platform. To view photos from many of the outside installations we have, please feel free to contact our office.

AC Unit on Electrical Cabinet. - The unit can be mounted on the cabinet�s High power (480v), side. It is in close proximity to the location that the drives are located. This option maintains the cabinet temperature and speeds up heat dissipation. All axes' servo drives are the major contributors to heat within the electrical cabinets.