Cnc Drill Line 10mm

Peddimat's interface is simple and intuitive. You can learn it in under an hour even if your computer skills are not the best.

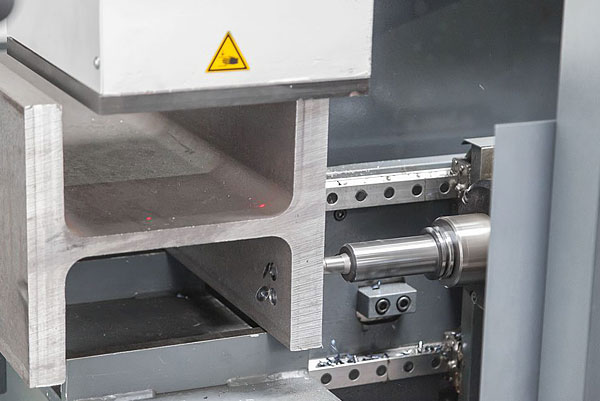

Advantage-2 utilizes a number of support clamps to maintain the maximum rigidity of the workpiece. Carbide tools last longer if there is as little vibration as possible.