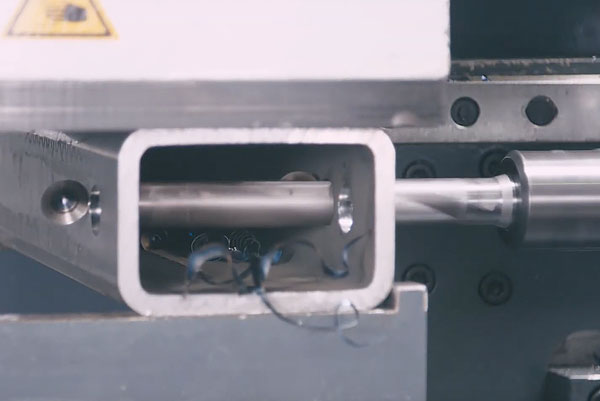

5mm Cnc Drill Bit

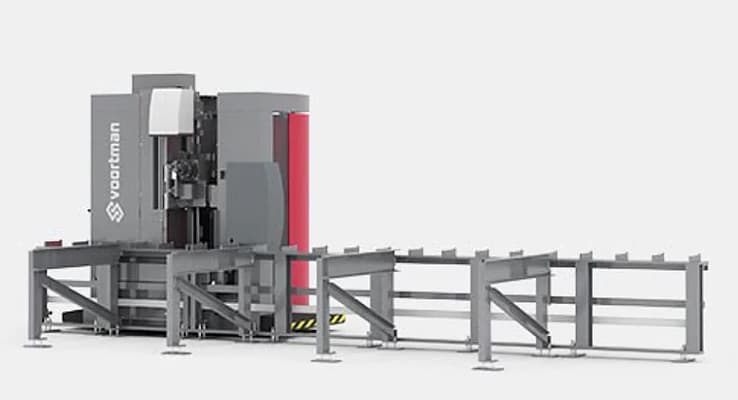

This range can move along the profile easily and offer a wide range of automated functions. It can process I andH beams, channels and flat bars, angle irons, channel, rectangular tubes, square tubes, and T bars respectively. Automated processing of already assembled metal profiles is possible without the need for programming.

CNC Drill Line is specifically designed for fabricators or general job shops who need to drill holes through steel profiles of all kinds. The following questions can help you decide if this machine is right for your needs.