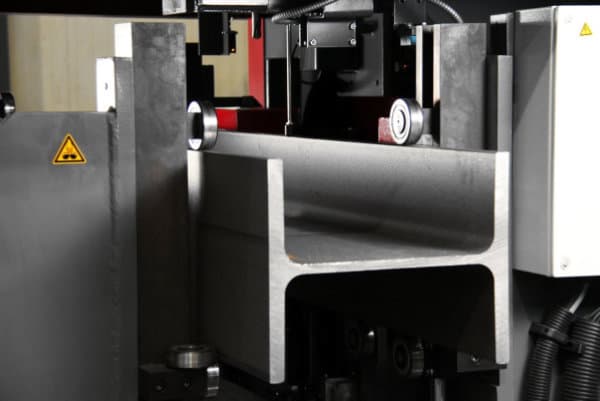

Cnc Drill Table

The CNC Beam Drill Line is a hit among small and medium fabricators, who can fabricate both structural steel as well as miscellaneous metals. The CNC Drill Line was first introduced in 2003 and has been used by more than 600 steel fabricators around the globe.

Z-Reader Probe-The Z-Reader Probe is a device that maps the location of the surface. It can be programmed or manually controlled. It can be disabled while cutting, and it can be pulled out of harm's reach. It can be activated to verify the surface at each pierce prior to cutting, or to drive surface mapping for the entire part before cutting begins. It is used to initialize or zero the device to the desired surface and then tracks or accumulates the difference between that zeroing effort.