E Z Lok Drill Chart

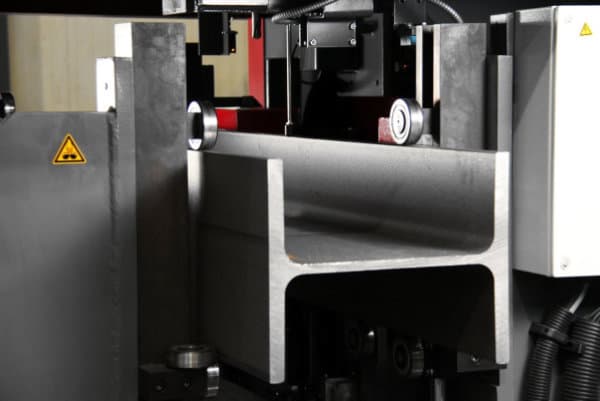

Voortman�s Roller Feed Measuring system surpasses industry standards in roller measurement technology. The key to accurate measurements is not allowing for any production hesitations. Even when there are material variations, accuracy must be maintained.

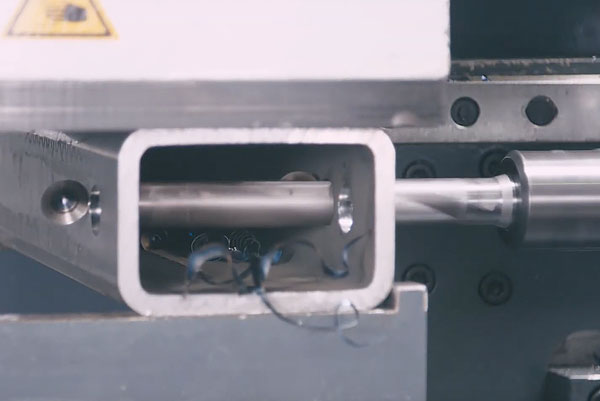

The CNC Drill Line has two options: it can be programmed in-house or at work using the Peddimat programming software. This software comes as part of the AVENGER. The unlimited license allows you to install it on as many machines in your workplace as you'd like. It's the same software found on your machine.