Cnc Drill Line Gap

".. Although the machine is targeted at structural fabricators, I found it to be very useful for drilling truck frames. This machine is very accurate and repeatable, which has made it easy to put together a truck frame. Avenger drills a series of channels for one truck within two hours. It takes 16 hours to do the same thing manually. This machine has dramatically increased our productivity, profitability, and efficiency !.."

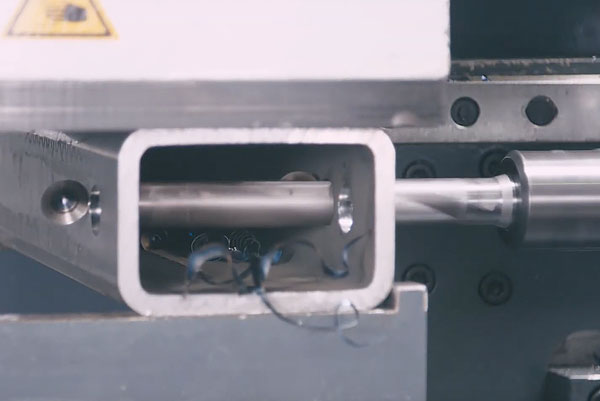

Voortman exclusively designed and built the CNC Drill Line to fit GSS Machinery. Voortman oversees all aspects of the CNC Drill Line, including warranty and service. Voortman acts as the service provider. GSS Machinery will always assist should the need arise.