Cnc Drill Line Net

GSS Machinery will provide you with as many options as you need when drilling with your CNC Drill Line.

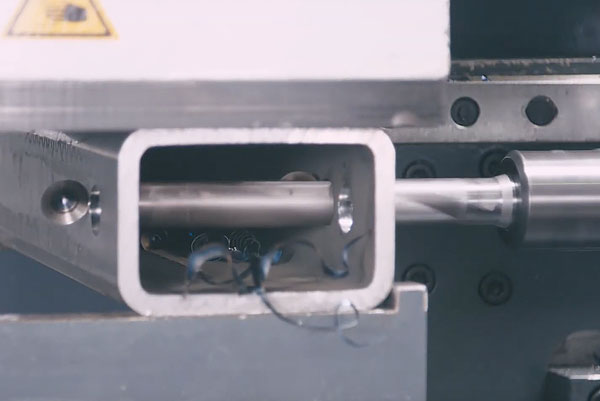

Voortman AccuMeasure Roller Feed measurement machine offers different saw measurements. AccuMeasure is flexible in handling and has a simplified CNC solution. Splitting apart a saw and drill allows each machine to work simultaneously, increasing production.