Tube Lasers Cutting Systems Japan

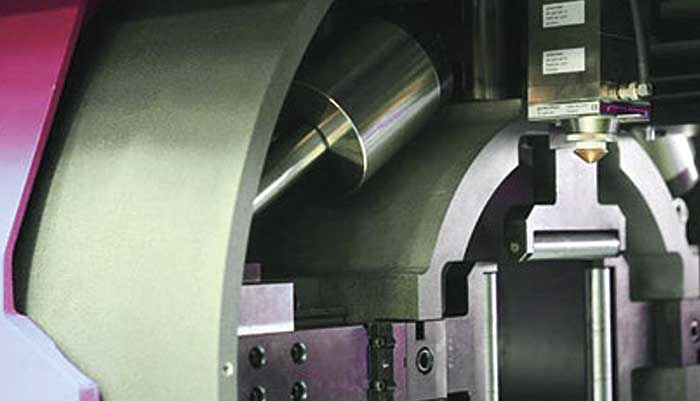

StarCut Tube L 600 comes with a fiber or USP laser. StarCut Tube SL, a compact model that has the smallest footprint available on the market, is the StarCut Tube SL.

How can this be compensated? Traditionally, you'd touch your face with the sensor at the contact area. The tube will then be rotated and the other end of it touched. This gives the control a good idea of the tube's bend. This technique is precise and will ensure that all through-holes work for your application. The ability to deliver very tight tolerances is affected by every rotation of a tube.