Tube Lasers Cutting Systems Richmond Va

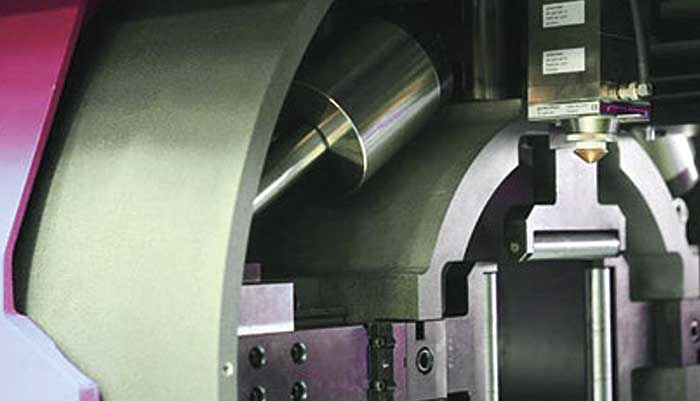

Built for maximum productivity, even for XXL tubes. With its robust solid-state laser, this machine can be used in numerous ways for the processing of tubes and profiles with a wide range of types of material and wall thicknesses.

Tubes are very simple and do not require a powerful laser. Tube laser cutting machines require only 5 kW power, whereas flat sheet laser cutters can be powered by laser generators up to 12 kW. When cutting a tube, it is important to always think about the other side. A stronger laser would simply blow through the tube on the opposite side during cutting. You don't need to worry about the other side if you're processing a beam of a channel or a channel using the tube laser.