What type of laser is most powerful

There are two options for laser cutting technology: 2D or 3-D. You can customize and cut parts in many different shapes. For example, you can make tubes that have round, square and rectangular shapes. Also, you can cut profiles with various open cross-sections like H, L, T and Ucross-sections. 3D technology can also be used to make bevel cuts as high as 45degrees. This versatility makes it possible to eliminate the need for expensive milling, drilling and punching as well as sawing.

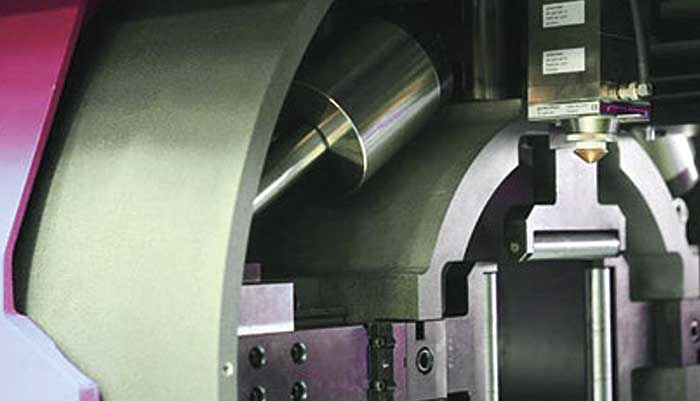

Some things are very obvious. A fiber laser's laser generator is smaller than a CO2 resonator. The fiber laser is actually made from banks of diodes, which are assembled in a module the size of a briefcase. It can produce power from 600 to 1,500 Watts. The final powered resonator is made up of multiple modules that are connected together. It can be as small as a small filing cabinet. Fiber-optic cable amplifies the light produced and channels it. The light that exits the fiber optic cable is exactly the same as it was when it was generated. There is no loss in power or quality. The light is then focused and adjusted to determine the material that will be cut.