Tube Lasers Cutting Systems Of America

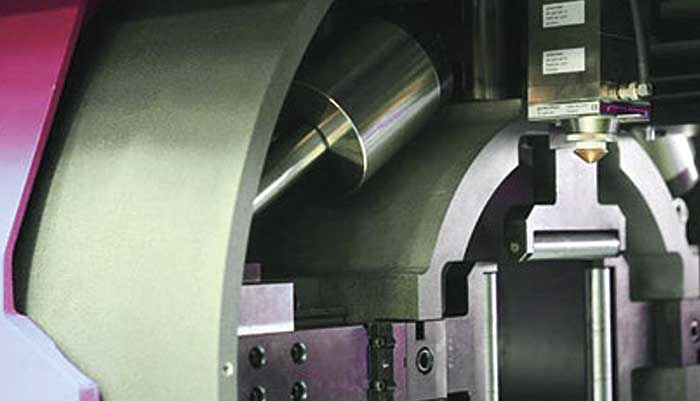

Some things are quite noticeable. The laser ďgeneratorĒ on a fiber laser is much smaller when compared to a traditional CO2 resonator. In fact, the fiber laser is created by banks of diodes that are put together in a briefcase-size module that can range in power from 600 to 1,500 watts. Multiple modules are spliced together to create the final powered resonator, which is typically the size of a small filing cabinet. The light generated is channeled and amplified through fiber-optic cable. When the light exits the fiber-optic cable, it is the same that is was upon being generated with no loss of power or quality. It is then adjusted and focused for the type of material to be cut.

Another consideration in tube cutting is the weld seam. This material is roll-formed and welded together. This brings up two points that typically must be addressed: