How do tube cutters work

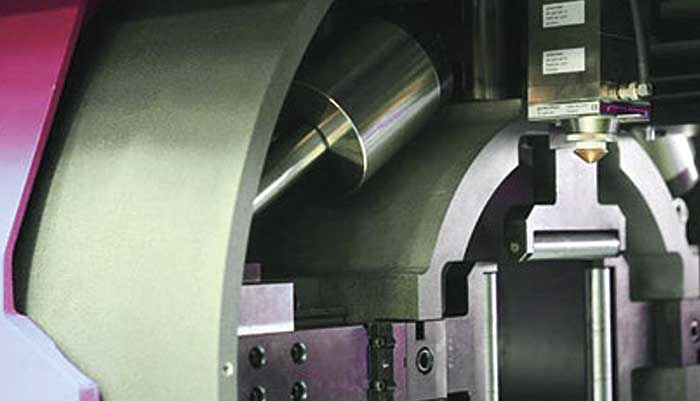

StarCut Tube L 600 has a choice of three laser options: a fiber laser or a USP. StarCut Tube SL has the smallest footprint of any model on the market.

A CO2 laser requires more power to produce than a fiber laser. This makes it less efficient and has lower wall plug efficiency. You will also need to use more power for the large CO2 laser chillers. Because the fiber laser-resonator's wall-plug efficiency is greater than 40 percent, it uses less power as well as less of your in high-demand flooring space.