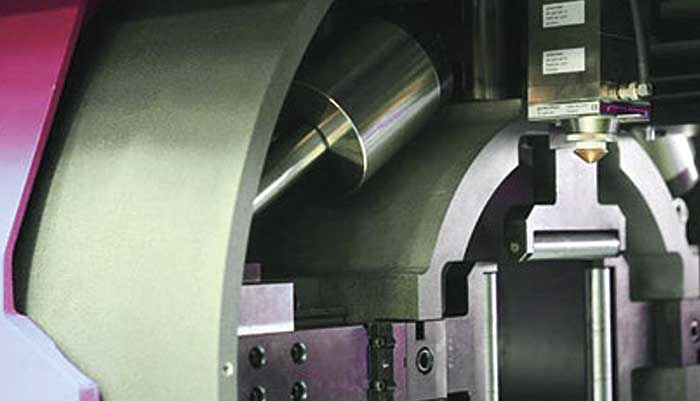

Tube Laser Cutting Systems Number Plate

Reduce secondary operations: A tube-laser can cut a piece to size and add holes and other cutouts in one step. It eliminates the need to perform secondary actions or manually remove material. It is possible to keep tight tolerances even on complex fabrications. Parts can be made from one continuous piece. They are easy to put together and fit perfectly. We can also tube laser carbon, stainless steel, and aluminum.

Let's take a look at the benefits of an automated tube and section bar storage with a Lasertube cutter system.