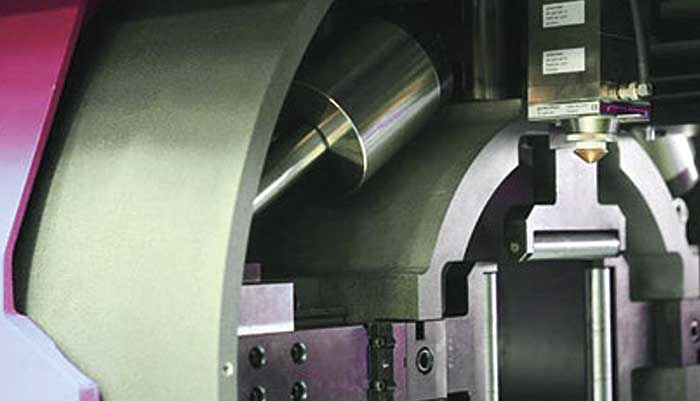

Tube Laser Cutter

Leading manufacturer of laser-cutting solutions, including CNC controls and automation systems.

There is no need to coordinate multiple orders or vendors. Gulf States Saw & Machinery Co., Inc. handles everything, from material procurement to past deliveries.