Parts

The laser beam generated is amplified, then fed to the cutting head via a flexible optical fibre.

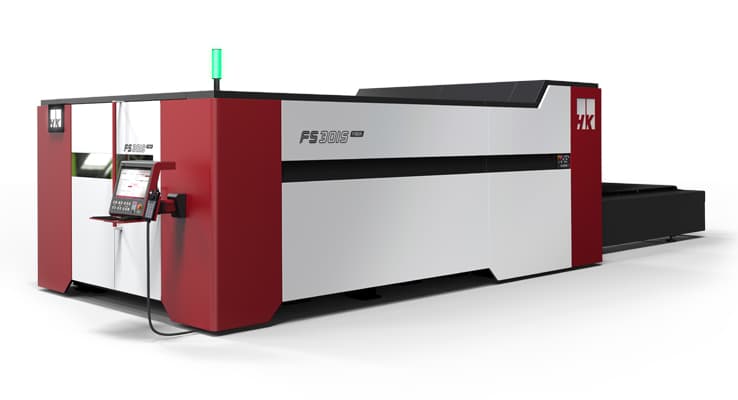

For the most demanding fabrication requirements, with thick materials and no room for error, our CO2 lasers can give your products and your business a serious edge.