Watts Brand

Here are a few things you should also know about laser and plasma when it comes to operation and maintenance:

Fiber lasers can be expensive so if you are looking for a low-cost laser engraver, you should consider diode lasers.

What is the most powerful laser you can legally own

MCWlaser PRO has an adjustable Z-axis, moved manually up and down with a control wheel. Unfortunately, XY axes are not adjustable.

Fiber lasers are very popular in engraving applications. They have wavelengths ranging from 780nm up to 2200nm.

Finally, the laser beam can be shaped at the cutting heads using focus lenses and projected onto the materials.

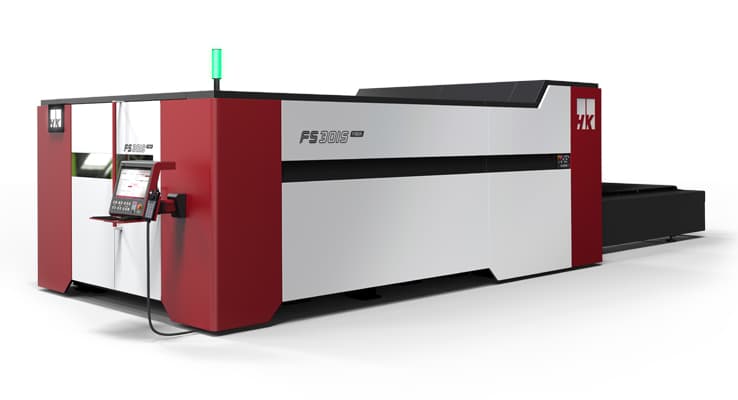

Affordable 5x10 industrial fiber laser metal cutting machine ST-FC3015LR is used for metal tube cutting and metal sheet cutting all in one. Now the industrial 5x10 laser sheet metal & tube cutting machine for sale at cost price.

Here are a few things you should also know about laser and plasma when it comes to operation and maintenance:

Fiber lasers can be expensive so if you are looking for a low-cost laser engraver, you should consider diode lasers.

GSS Machinery also provides auto-loading and unloading systems that can be integrated with fiber laser machines for maximum automation, increasing speed and efficiency for your processing requirements.

MCWlaser PRO does not offer an upgrade, but you can modify it during purchase.

When buying safety glasses for this machine, make sure to buy one which is designed to block 1064 nm laser light.

It is important to remember that a fiber laser has limitations in terms of both the size of your work-bed and the material you can cut.

Gulf States Saw & Machine Co. (FM1212-50S) does not include assembly. The modules can be attached to the machine by simply referring to their manual.

Profitable 5x10 CNC fiber laser metal cutting table ST-FC3015GC has higher cutting speed and quality compared to other metal cutting solutions. It adopts an up and down exchange platform, able to finish the platform exchanging within 15s for commercial use. Now the best fiber laser metal cutting table for sale at affordable price.

It means that when working with metals that reflect laser beams they absorb fiber laser light much faster than the CO2 laser light.

Fiber lasers use high-power laser diodes to stimulate active medium and pump optical fiber with laser light.

The wavelength is the primary distinction that determines the types of materials that each laser can process. The wavelength of a fiber laser is typically 1,060 nm, whereas CO2 lasers have wavelengths in the 10,600 nm range. Fiber lasers have many advantages over CO2 lasers in general.

Because the glass is transparent and the wavelength range of the automatic fiber laser cutting machine does not fall within the absorption range of the glass, it only absorbs a small amount of laser energy within the visible spectrum and cannot be cut by fiber laser.

Compressed air, nitrogen, oxygen, and argon are the four primary types of assist gas for fiber laser machines.