China

LaserWorks, RDWork, or LaserWorks software control the machine. Download them from their respective websites.

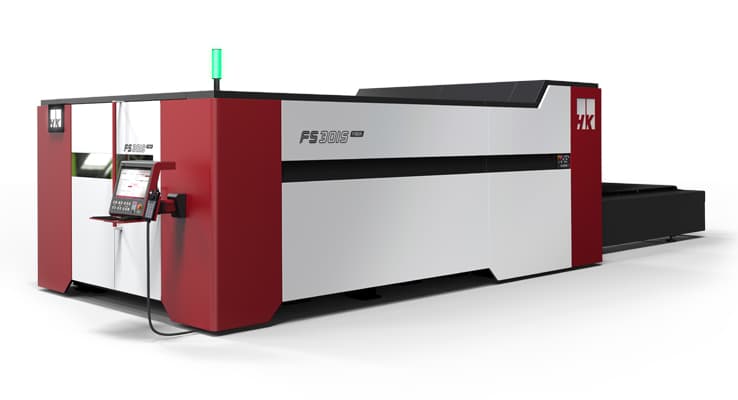

Our fiber laser machines use a low-maintenance solid-state laser source to generate a laser beam that is transmitted to the laser cutting heads via fiber optic cable. These fibers move the beam with a beam quality optimized for metal cutting. GSS Machinery provides laser power ranges of 1000W, 1500W, 2000W, 2500W, and 3000W, with a cutting velocity of 35 minutes for fast and precise operations.