Mactron

Plasma can also cut glass or ceramic. Because they are electrically conductive, plasma can't cut through plastic or wood.

For after-sales services, you can contact them through phone, e-mail, or through their social media handles.

How is laser cutting rate calculated

Our machines can cut steel, brass and aluminum without any back reflections. These fiber laser machines can reduce maintenance and operating costs.

Boss Laser provides the FM-Desktop laser engraver in three laser configurations, 20W, 30, and 50W. You can pick them depending on what you need.

A Raycus 50W Fiber Laser allows you to engrave in stainless-steel at a 90 degree angle using a speed of 3,540 IPM by using 100% of the laser power.

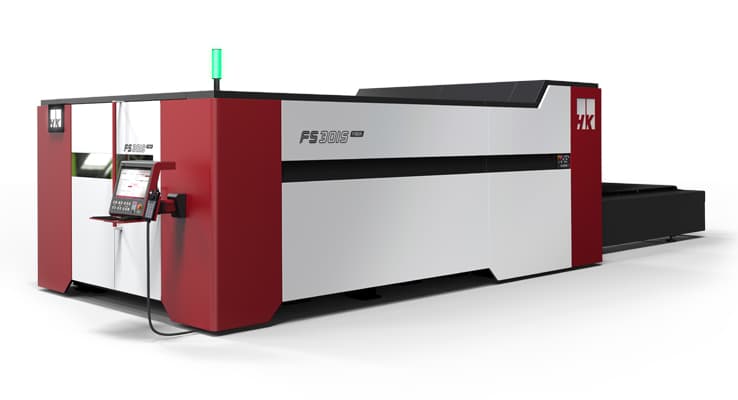

6x12 high power fiber laser metal cutting machine with exchange pallet has faster cutting speed and high power laser source (1000W, 2000W, 3000W, 4000W, 6000W, 8000W, and up to 40000W) compared to other cutting solutions for commercial use, now the high power laser cutting machine for sale at affordable price.

Plasma can also cut glass or ceramic. Because they are electrically conductive, plasma can't cut through plastic or wood.

For after-sales services, you can contact them through phone, e-mail, or through their social media handles.

The fiber laser is capable of achieving a repetition precision of +-0.0001" while producing a beam quality of less that 1.1 M2.

LaserWorks or RDWork software is used to control the machine. These software can be downloaded free of charge from the respective websites.

There are also options for engraving areas of 6.9"x6.9", 5.9'x5.9", 4.3", 4.3", 2.6"x2.6", and 4.3". You can choose one or more depending on your operational requirements.

When it comes to cutting various Fiber laser machines are more efficient at cutting thin metals. A fiber laser machine can cut thin metals efficiently up to 25mm or 1 inch. After that, fiber lasers start cutting metal less efficiently. You would need high amounts of power, which by the way cost a lot more money, to cut ticker metals above 25mm or 1 inch.

FSL Muse Pandora is upgradeable with a special focus lens, a rotary-axis, extended Z-travel, fume extractors, and fume extractors.

When using fiber laser machines to cut projects, it is necessary to learn the use and maintenance skills, in order to better exert the effectiveness of the equipment and maximize the efficiency of the equipment. 1. Check the steel belt frequently to ensure the tension. Otherwise, if something goes wrong during operation, people may be injured and serious death may result. The steel belt looks like a small thing, but the problem is still a bit serious. 2. Check the straightness of the track and the verticality of the machine every six months, and find that it is abnormal and timely maintenance and debugging. Without this, the effect of cutting may not be very good, the error will increase, affecting the cutting quality. This is the top priority and must be done. 3. Use a vacuum cleaner to suck off the dust and dirt in the machine once a week. All electrical cabinets should be closed and dustproof. 4. The guide rails should be cleaned frequently to remove dust and other debris, to ensure that the equipment racks are cleaned frequently, and lubricating oil is added to ensure lubrication without debris. The guide rail should be cleaned and lubricated frequently, and the motor should also be cleaned and lubricated frequently, the machine can move better during cutting, cut more accurately, and the quality of the cut product will improve. 5. If any damage is found in the process of using the machine, it must be replaced in time, which is not only a type of protection for the machine itself, but also ensures that the machine always maintains an ideal cutting effect.

FSL Muse Pandora 20W can deep-engrave silver at speeds of up to 708 ipm, using 100% of the laser power

The generated laser beam is then amplified and fed to the cutting head using a flexible optical fiber.

Fiber lasers leave unsightly marks on wood.

The goal of any marking or engraving project is to create a readable mark, whether by hand or machine. Uncontrolled absorption, on the other hand, results in an uncontrolled mark on the wood.

Maximum material cutting thicknesses by 1000W fiber laser cutting machine: Carbon steel has a maximum thickness of 10mm; stainless steel has a maximum thickness of 5mm; aluminum plate has a maximum thickness of 3mm; and copper plate has a maximum thickness of 3mm.

Fiber lasers typically cost between $20,000 and $45,000.