How much does it cost to run a laser machine

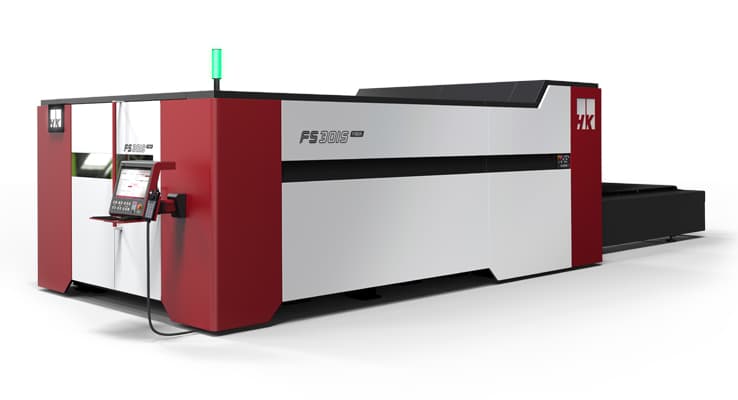

There are several laser power options available: 1000W to 1500W, 2000W to 2500W, 2500W to 3000W. These fiber laser machines are fast and precise, with a cutting speed of 35 meters per minute. Laguna Tools also offers machines that have an enclosed area for reducing light pollution.

With Triumph's 30W desktop fiber laser, you will get two lenses. One gives 4.3" x 4.3", and the other gives a 7.8" x 7.8" engraving area.