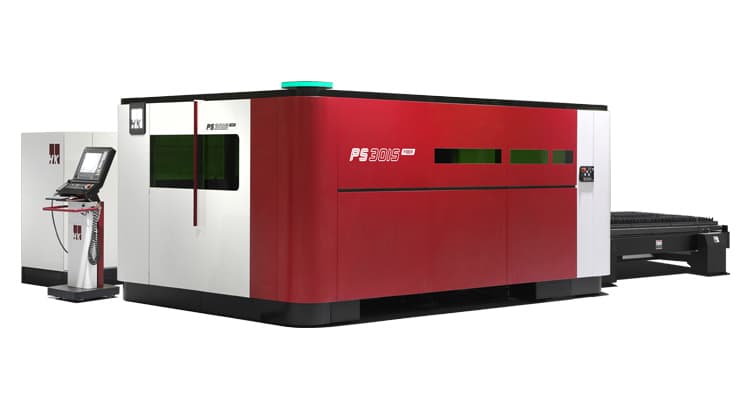

Fiber Laser Machinery Zinc

Our Fiber laser cutting machines can cut through any metal range smoothly and precisely. It also enables metal fabricators to integrate high-level precision cutting capability into their workshop operations for superior cut quality. It is also highly regarded for providing excellent featured cutting on materials ranging from gauge to plate thickness as well as titanium, brass, mild steel, copper, aluminum, stainless steel, and many more.

The laser used is a pulsed fiber laser with a wavelength of 1064 nm. It has an estimated lifetime of 25,000+ hours.