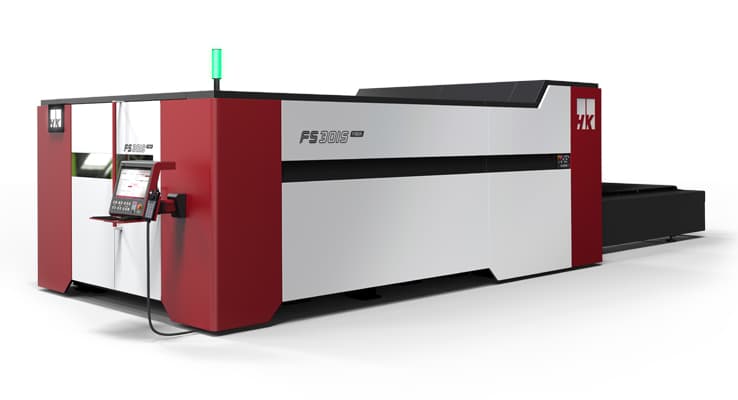

Fiber Lasers Machinery 6 Bench Grinder

It is capable of engraving at speeds up to 11,760 ipm. It can mark intricate fonts and images on uneven or smooth metal parts.

Laser uses light to cut metal. Light is concentrated into a single point to be able to pierce and cut metal. Just think of a magnifying glass that can be used to focus sunlight into a single point and burn it. That�s how cutting with light pretty much works.