How much does a laser engraver cost

A 30W or 50W fibre laser is required to improve the engraving area to 7.87 x 7.87 x 11.87 x 11.87".

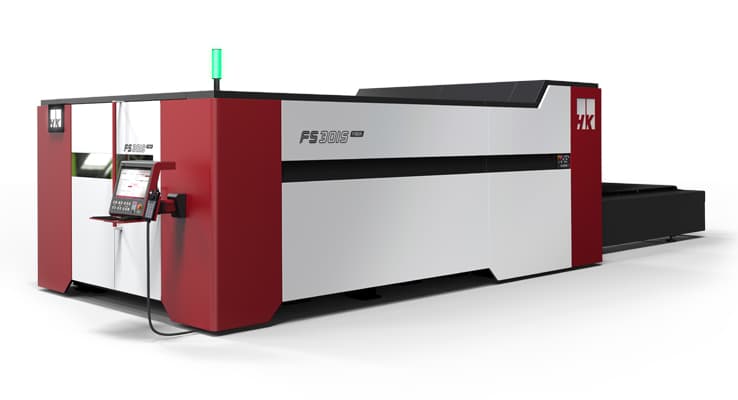

Triumph's 30W desktop fiber laser can engrave on aluminum, gold, silver, steel, stainless steel, copper, and some plastic-like polymer for metal tools and machine parts.