Fiber Laser Marker Machine

RetinaEngrave.0 can import files from all CAD programs.

Additional accessories, like a fume extractor lens or a lens, are available to upgrade the machine.

Can a 50W fiber laser cut metal

Triumph Laser has EZCAD2.0 laser control software that can be used with their desktop 30W laser engraver machine. EZCAD2.0 can be used to make simple shapes or text.

If you stare at the fiber laser cutting machine for a long time, it will cause very serious damage to the retina of the eye. All operators must wear laser goggles. Do not operate and observe with eyes exposed. In the cutting path of the laser equipment, it is necessary to avoid the position of any part of the body, so as not to accidentally cause unnecessary injury.

Fiber Laser Machine DistributorsCarbon steel, stainless steel, silicon steel, alloy steel, spring steel, mild steel, aluminum, galvanized steel, tool steel, aluminized zinc plate, copper, brass, pickling sheet, titanium, silver, gold, iron, alloy, and other metal sheets and tubes.

2022 top rated affordable laser tube cutting machine with fiber laser source is an automatic CNC metal pipe cutting system used to cut patterns in square, round, rectangular, oval, and special shape tubes. Now the best budget fiber laser tube cutter for sale at cost price.

RetinaEngrave.0 can import files from all CAD programs.

Additional accessories, like a fume extractor lens or a lens, are available to upgrade the machine.

Some PVC-based acrylic emit toxic fumes during lasering. It is a good idea to research the chemical compositions and materials you will be engraving.

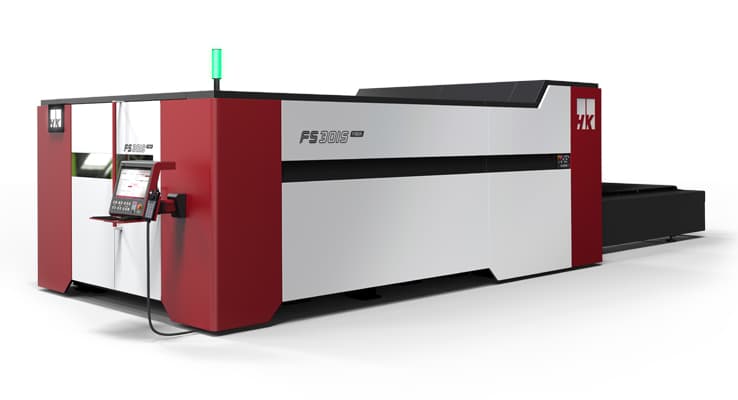

AMADA engineered the 3kW ENSIS 3015 RI to include an innovative Rotary Index with the power and speed to efficiently transition from flat sheet to tube or pipe cutting. Incorporating fiber laser cutting technology helps users process a variety of tubing and pipe with greater speeds compared to a CO2 system.

MCWlaser PRO is a split-type machine, which means the laser source and the engraving machine come in separate modules.

It�s the perfect solution for fabricators facing worker shortages and bottlenecks resulting from the increased productivity of higher-volume fiber lasers.

This laser is a pulsed laser fiber laser with 1064 nm wavelength. It has a life expectancy of approximately 25,000 hours.

Fiber lasers are widely used for engraving on metals as they can engrave more effectively than generic CO2 lasers.

Since the working medium adopted by the laser generator is in the form of an optical fiber, its features are affected by the transition properties of the optical fiber. The pump light entering the fiber generally has multiple modes, while the signal photoelectric may have multiple modes. Different pump modes have different effects on different signal modes, making the analysis of laser generators and amplifiers more complicated. The doping distribution in the fiber also has a great impact on the laser generator. In order to make the medium have gain characteristics, working ions (that is, impurities) are doped into the fiber. In general, working ions are evenly distributed in the core. However, the distribution of pump light of different modes in the fiber is non-uniform. Therefore, in order to improve the pumping efficiency, the ion distribution and the pumping energy distribution should be as close as possible. When analyzing the laser generator, in addition to the general principle of the laser generator discussed above, it must also consider its own features, introduce different models and adopt special analysis methods to achieve good analysis results.

Fiber lasers are used to engrave on metals because they can engrave better than generic CO2 lasers.

To guide light, fiber lasers use an optical fiber cable made of silica glass. Because the resulting laser beam is straighter and smaller than with other types of lasers, it is more precise. They also have a small footprint, are energy efficient, require little maintenance, and have low operating costs.

In fact, the diode module in a fiber laser typically outlasts other technologies by three times. Most lasers have a lifespan of about 30,000 hours, which equates to about 15 years of use. Fiber lasers have an expected life of 100,000 hours, which equates to 45 years of use.

Power consumption is extremely low.

A 3000W fiber laser requires 10kW of power plus 5kW for a chiller, for a total of 15kW. $2,700 per year at a rate of 15kW per hour for 12 hours.