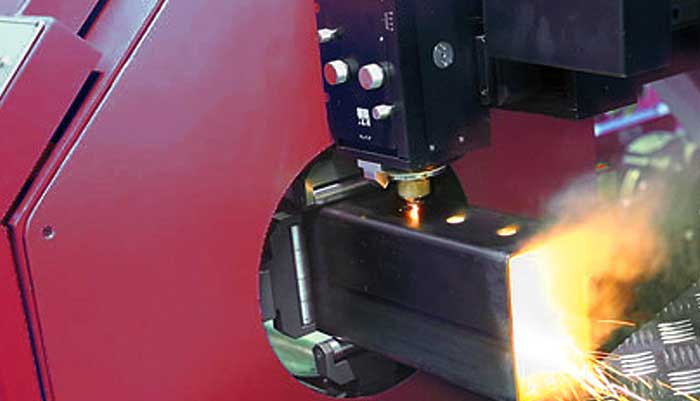

Tube Laser Cutting Systems 50w

For large diameter tubes or profiles, CO2 is the best choice. Tubes up O 14/24" (355 mm/ 610mm) 3D cutting modeCO2 laser

The shape laser technology allows you to customize and cut-to length in one step. From raw material, finished or semi-finished parts can be produced.