Tube Laser Cutting Systems Uses

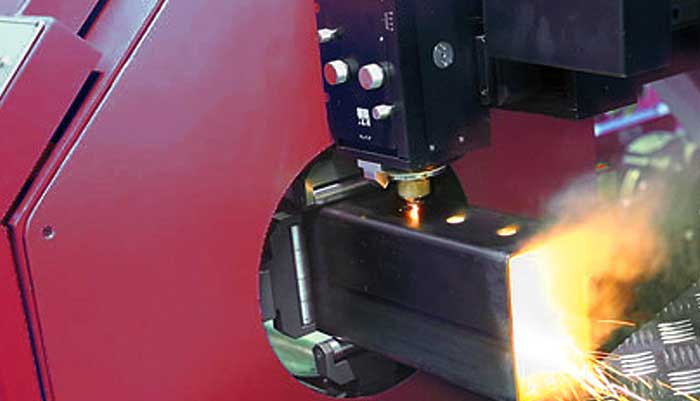

ExactCut 430 allows for precise laser cutting of metals and alloys. It also automates the production of brittle materials like ceramics, sapphire, and PCD.

With a rock-solid cutting platform (the SL uses a mineral cast base) these machines offer the ultimate in precision, with contour cutting accuracies better than +/- 5 Ám. A choice of fiber laser or the latest Monaco USP laser enables fine cutting of any polymer or metal.