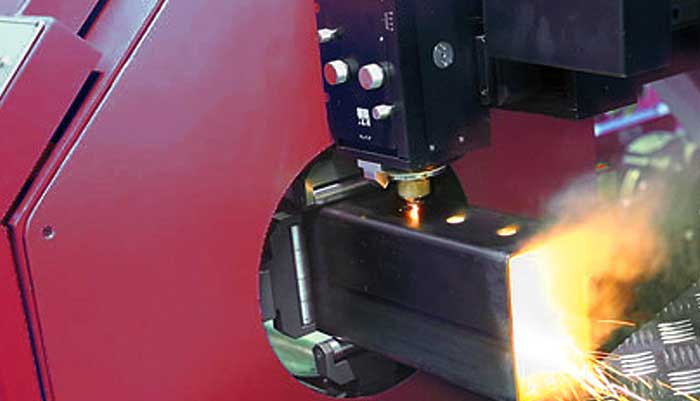

Laser Tube Cutting Machines Blm Group

This is the easiest way to enter tube laser cutting. Tubes upto O 4,72" (120mm)2D CutFiber laser

You may have noticed we havenít covered cutting speed. Although you can cut up 500 inches per minute using a tube cutter, it's not always practical. Laser tube cutting involves focusing on the time required to load a tube, index the tube so it's in a good position for cutting and then pierce, cut and unload the part. It is not about cutting speed, but part-processing time when laser tube cutting machines are used.