Tube Lasers Cutting Systems Europe

Let's now look at the benefits associated with an automatic tube and section-bar storage system combined with a Lasertube Cutting system.

Leaders in advanced laser-cutting solutions and CNC controls.

What are the disadvantages of a laser cutter

It is important to remember that traditional ways of checking for twists and bows can take up five or seven seconds, before cutting can begin. Touch sensing can only be used for precision. It can seem that this is all a lot, but it's not the same as working with sheetmetal.

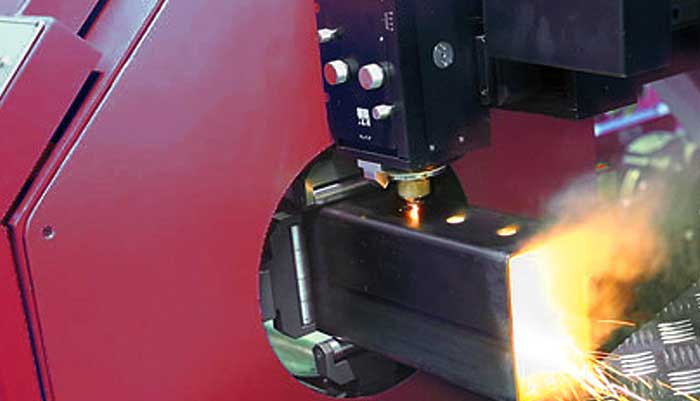

This is the most effective solution to any tube section. Tubes upto O6" (152.4 mm).2D cutterCO2 or fibre laser

Our system solutions allow for flexible production of small or large series with diameters from 10 to 324 millimeters, and pipe and profile lengths as high as 12.5 meters.

Let's examine the benefits of using an automated tube storage system and section bar storage system in conjunction with a Lasertube-cutting system.

Let's now look at the benefits associated with an automatic tube and section-bar storage system combined with a Lasertube Cutting system.

Leaders in advanced laser-cutting solutions and CNC controls.

Many of Gulf States Saw & Machinery Co., Inc.ís tube laser-cutting systems integrate intelligent machine functions which include intelligent monitoring, setup and cutting functions. These automated functions improve ease of operation and machine efficiency. The extensive range of capabilities of Gulf States Saw & Machinery Co., Inc.ís tube and pipe lasers makes these machines ideal for many industries and a variety of applications.

Lasertube can help you make improvements to parts based on your customers' needs.

Built for maximum productivity, even for XXL tubes. With its robust solid-state laser, this machine can be used in numerous ways for the processing of tubes and profiles with a wide range of types of material and wall thicknesses.

Motion Dynamics is a major manufacturer of neurological sub-assemblies. They include steerable catheters as well as "pull wire" assemblies. Our StarCut Tube machines are used to precision cut key components.

A tube is very flexible and does not require a high-powered laser. Laser generators with a power output of 12 kW are now possible for flat sheet cutting machines. Tube laser cutters require a power consumption of only 5 kW. To cut a tube you must always look at the opposite end of the tube. A stronger laser would simply blow through your tube while cutting. (Officially, if the laser is processing a beam and a channel on the tube's laser, there are no need to worry about any other side.

High cutting quality is one of the main characteristics of CO2 Lasers. Their primary application is in medium to high material thicknesses. The laser beam's cutting edges offer high throughburr and low scoring. This makes it possible to process the cut parts further without having to rework.

NIT uses a Coherent Laser Cutting Machine to Vertically Produce Nitinol and Other Metal Components with outstanding precision and edge quality.

North America's top magazine for the metal forming/fabricating industry is The FABRICATOR. The magazine offers news, technical information, and case histories to assist fabricators in doing their jobs more efficiently. Since 1970 the FABRICATOR served the industry.