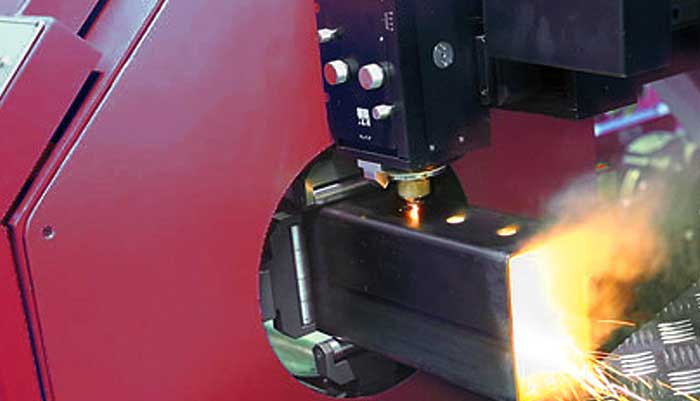

Fiber lasers are 10 percent shorter than CO2 laser beams in wavelength. Because of its shorter wavelength, fiber lasers produce a beam that is easier to absorb by reflective materials. A CO2 laser's wavelength is less likely to reflect off these surfaces. This allows fiber laser cutting machines to cut brass, bronze, and other reflective material. A CO2 laser beam that reflects on the material can damage not only its cutting lens, but the entire beam path. This risk can be eliminated by using fiber-optic cables to guide the beam.

Gulf States Saw & Machinery Co., Inc. has a team of experts that will work with you to develop a program tailored to your requirements. We'll examine how your part is being made, evaluate its use or application, then work with your to determine and fulfill your requirements.