The very nature of a tube prevents the need for a machine with a very high-powered laser. Whereas flat sheet laser cutting machines now are available with laser generators as powerful as 12 kW, tube laser cutting machines usually only require a maximum of 5 kW of power. With a tube, you always have to think about the opposite side of the tube you are cutting. A more powerful laser simply would blow through the other side of the tube during cutting. (Of course, if you are processing a beam or a channel on the tube laser you don’t have to worry about another side.)

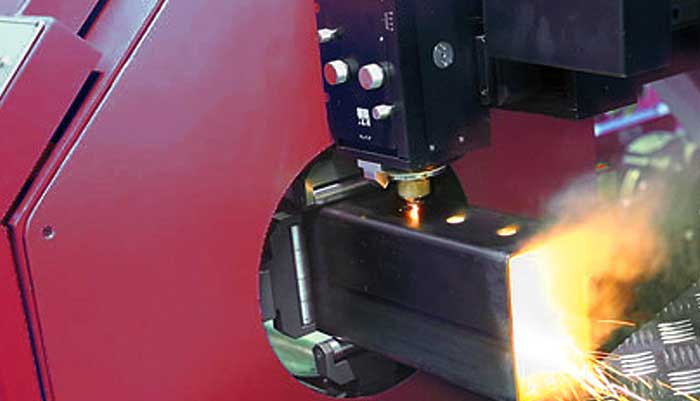

Profiles and tubes are widely used in all areas of engineering, from system construction to furniture manufacturing. The lasers have opened up new design possibilities. More and more designers are taking advantage the advantages of laser-cut profiles and tubes, thereby increasing their demand. Explore all the options for laser tube cutting, and learn more about TruLaser Tube machines.