Tube Lasers Cutting Systems Zurich

How can you compensate for this? Traditionally, you will touch your face with a sensor marking the contact point. The tube is then rotated and the opposite end of the tube touched. The control will then be able to see how bent the tube looks. This allows for precise measurements and ensures that the through-holes will work properly. Keep in mind, however, that every rotation of the tube reduces the ability for very high tolerances.

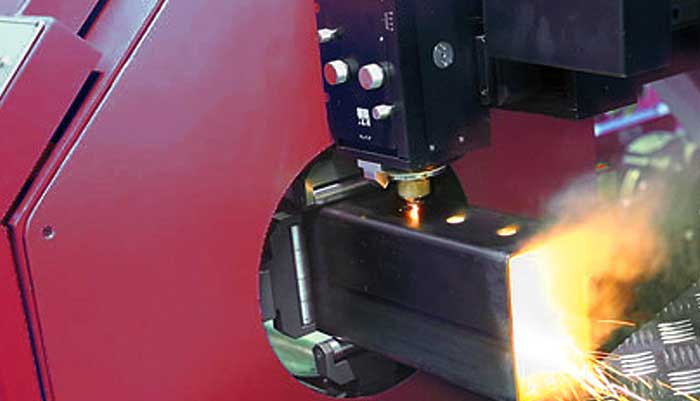

StarCut Tube L 600 is available with a fiber laser, a USP laser or both lasers. StarCut Tube SL is a compact model with the smallest footprint in the market.