Cad

CNC Drill Line is able to import DXF files. It can then use these files to create 3-D shapes, provided that the steel has been detailed according to certain rules. These rules may not be applicable to your current detailing and might need some adjustments. This process is not as smooth as the 3-D modeling software.

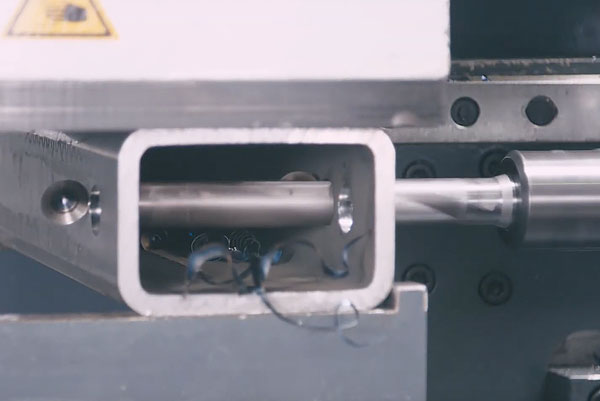

Renishaw 5-Axis Calibration - This calibration unit is a Renishaw model APCA45, with a modified spherical tip. To remove dust and debris during activation, the device comes with a retractable cover. It attaches to a swing arm that is controlled by a pneumatic motor. This allows it to be out of the way during normal operation, and then swings into the calibration position.