Akyapak

Voortman has a reputation for providing exceptional service and support. This is the benchmark in the industry. Voortman's customer support team is global and available around the clock at the Voortman 24/7 customer support centre. Voortman provides support through a state-ofthe-art remote diagnostic program, easily accessible local field support and the industry's leading warranty.

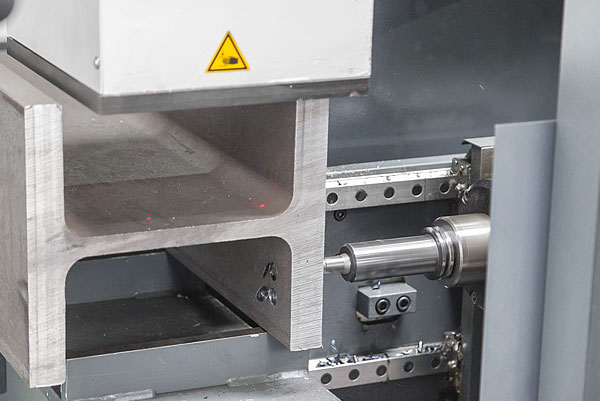

".. ". It has been easy to assemble the truck frames without any errors due to its repeatability and accuracy. Avenger drills channels for one truck in under two hours. This is compared to 16 hours if we had to do it manually. The machine has significantly increased our productivity and profitability !.."