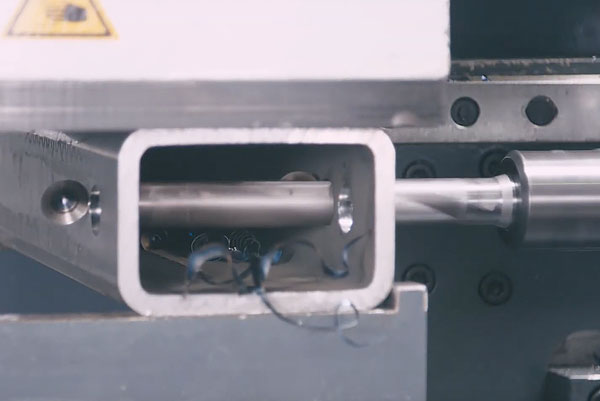

What good is a CNC drill line if it doesn't position a fabricator to compete at a high level in the steel fabrication arena. The Advantage-2 has the functionality to process technical programs with intelligence and speed. Equipped with three five-station tool changers, each drilling axis has the capability to drill, mill, countersink, tap and scribe. This drill line can also be equipped with a Signoscript underside scriber or Signomat part stamping unit. Part information is retained even after painting, blasting and galvanizing processes. Minimizing shop errors? Check. Carbide tooling gives the Advantage-2 more aggressive drilling and a higher quantity of holes than any drill line before it. The high torque drilling axes have a thicker more aggressive cut removing more chips with each rotation. This drill line will chew through beams, channel, angle, tube and even flat bar. With a processing window of 44 inches wide and 18 inches tall no profile can escape the reach of the Advantage-2.

Material handling is a way to tie together multiple CNC machines. It also keeps material flowing through a shop, which allows fabricators grow their businesses. The Advantage-2 high-speed drill machine can handle 150 tons of steel in an average 40-hour week. This is the ideal drill line for small- to large fabricators around the world. The end. Voortman places the success of steel industry as its top priority. We are proud of our unsurpassed service and support. Call, request a demo or quote to find out more about the best steel fabrication machinery. Voortman is the name of our company and we are more powerful than steel.