Cnc Beam Drill Line Drawing

GSS Machinery is committed to offering you the best options for drilling with your CNC Drill Line, or any other CNC Beam Drill Line.

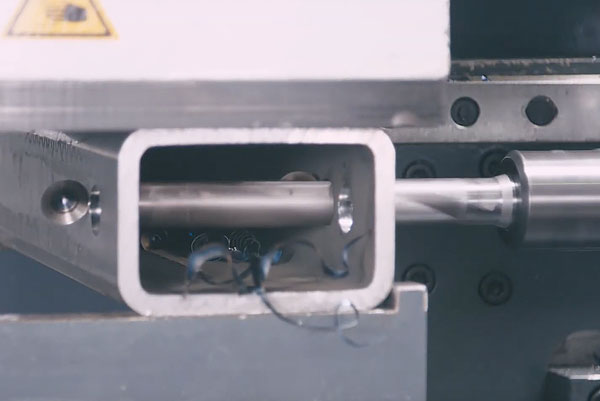

The ability to mill copes speeds up project completion times tremendously. Coupled with the Advantage-2 user-friendly Raptor 3D CAD/CAM software enables the operator to program parts quickly. Inspect, modify and export part information directly within the 3D platform. The biggest advantages of the Advantage-2 drill has been probably the scribing and the ability to mill slots, large lifting holes. I mean this really kind of sets this machine apart. With the scribing we're able to put piece marks and layout lines, center points. I mean having that flexibility to use it when we want to and make that decision has been really great.